Why innovation benchmarking?

The growth dynamic of many chemical companies has clearly decreased in recent years. Companies are even more under pressure to generate new growth through innovation. Our Chemical Innovation Benchmarking which is based on a benchmarking database with 300+ companies supports our clients in the chemical industry to improve their innovation capabilities and increase their Return-on-Innovation.

When to apply innovation benchmarking?

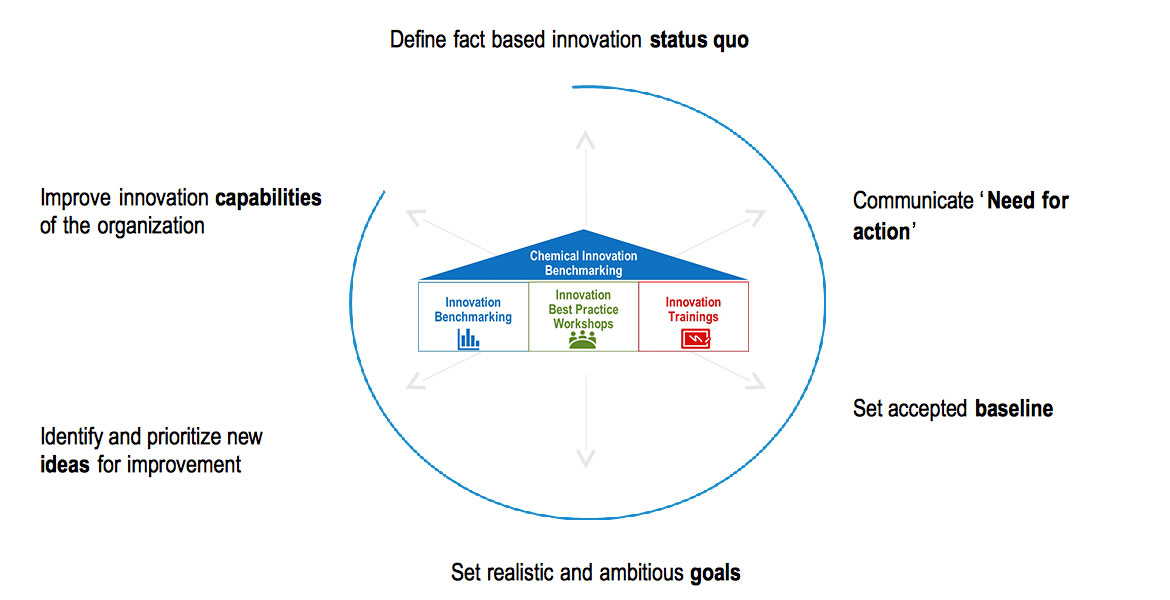

Chemical Innovation Benchmarking supports the optimization of the innovation engine in different stages. It is a value adding tool to get ideas for best practices or to trigger improvements. Benchmarking is also a very efficient tool for communication and change management – especially in technically driven industries like the chemical industry.

How to use innovation benchmarking?

The core of the benchmarking is a benchmarking database containing more than 60 success factors from more than 300 companies from multiple industries with deep dives for the Chemical Industry.

We offer our clients to benefit from the benchmarking data and best practices in three different ways. With a benchmarking project our customers can compare their performance in more than 60 success factors with selected benchmarking target groups. Our best practice workshops are a very efficient way to improve in selected topics like project portfolio management or innovation culture and use best practices from our benchmarking database. Finally we offer innovation trainings which are built on the best practices.

® Innovation Success Panel is a registered trademark of Prof. Dr. Holger Ernst

INNOVATION BENCHMARKING

Our Innovation Benchmarking delivers a status quo analysis and the key improvement opportunities and individual recommendations in a very efficient manner. Our database with more than 300 companies and 60 success factors provides a solid basis for the benchmarking. By comparing the external and internal view we achieve a high quality of our recommendations.

Our benchmarking projects contain the following steps:

- Conduct scoping meeting

- Plan and schedule interviews

- Gather data via interviews, survey and project reviews

- Consolidate findings of the analysis based on best practices

- Work out a benchmarking report with more than 60 innovation KPIs & parameters

- Present benchmarking results including improvement options and improvement measure proposals

INNOVATION BEST PRACTICE WORKSHOPS

The Best Practice Deep Dive Innovation Workshops offers the opportunity to discuss selected innovation topics more deeply. Based on a combination of briefing discussion, a survey and the best practices from our benchmarking database, solutions and action plans will be developed in an efficient workshop approach.

Our Service includes the following steps

- Conduct briefing discussion to scope topics

- Drive pragmatic upfront survey (10-15 questions)

- Prepare workshop based on briefing, survey and best practices / benchmarks

- Run workshop (typically 1-day offsite)

- Consolidate workshop findings and develop action plan for the challenge in scope

Typical topics for best practice workshops

- Developing the innovation strategy

- Measuring the innovation performance

- The Ideal size of the innovation organization

- Creating an innovation culture

- Managing and steering large innovation initiatives

- Additional topics for deep dive workshops on demand

INNOVATION TRAININGS

Based on our project experience and best-practice knowledge from the benchmarking we have developed trainings for innovation management topics in the chemical industry. The trainings will increase the competency level of the organization on innovation management – which is also an important building block to improve the innovation culture. Besides this, our trainings increase the team spirit. Most trainings include practical elements and can be conducted on-site or off-site.

We offer the following trainings:

- Pragmatic Project Management for innovation projects

- Success factors and best practices for innovation management in the chemical industry

- Portfolio management in chemical innovation portfolios

- Improving innovation culture

- Additional topics for training on demand